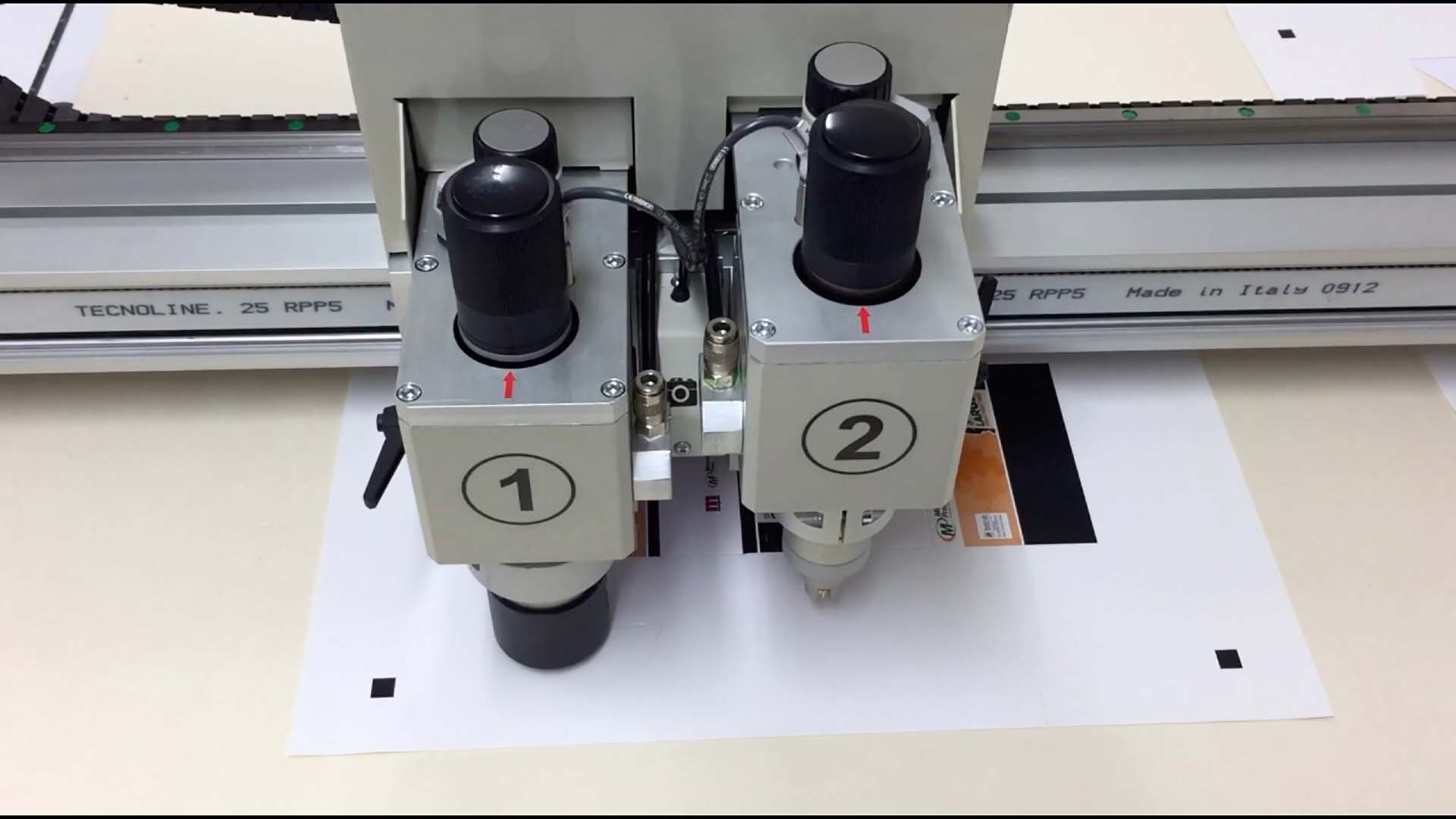

The possibility of creating a prototype of each new package and packaging product (whether made from scratch or from restyling an already existing package type) allows, before manufacture on an industrial scale, having access to an effective tool to monitor and control the package functionality and, for consumers, to touch and look at a realistic depiction of the way the final product will appear.

Print and cut technology allows packaging prototypes to be made with UV inks for high quality finished products. In addition, with UV technology, we can add stunning three-dimensional coating combined with four-color and white ink, allowing total control of Pantone color reproduction on the different materials used.

Printing with UV inks-Packaging

UV inks allow printing on several paper types, from the classic offset coated paper to the most prestigious specialty papers. In addition, the ability to print white and three different types of color opens the door to creative solutions until now only possible on high weights.

Today we have the opportunity to build prototypes and small batches with high added value, at a very low price, resulting in a unique final product. Thanks to our cutting devices’ use of special blades and a drilling function, we can make packaging with die-cut finishing.

Printing with UV inks-Soft Packaging

The UV inks allow printing on polyethylene and polypropylene, opening inkjet digital printing to the world of food packaging or, more generally, the world of packaging on flexible materials.

Graphic agencies or printers who need to present to the client the exact model of the finished product can now do so easily and professionally. The use of an extremely opaque white allows printing on transparent materials, widely used to show the buyer the product inside the packaging.